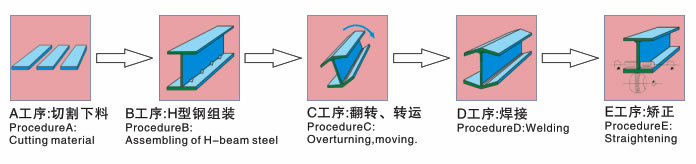

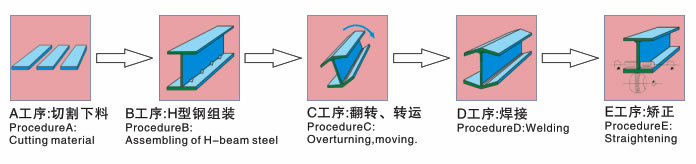

FOCUS can design and customize various type of specialH-Beam build up lineaccording to the technological requirement and different process capacity given by the customer, including light duty type and heavy duty.

Economical and practical light duty H-Beam build up line is be formed the multi-head strip(or cnc strip )cutting machine, H-Beam assembling machine, H-Beam welding machine, H-Beam straightening machine, H-Beam shot blasting machine.

Automatic mode heavy duty H-Beam build up line is widely used invarious metal structure enterprises domestically, the main features are automatic production flow of assembling, overturning, welding ,workpiece conveying and straightening are realized, smooth in technology ,high in efficiency.

Welding shaped H-steel (I-steel), as a result of thermal expansion and the role of its flange plate will inevitably produce distorted, Physics-40 aircraft will be used to correct its correction deformation of special equipment. The machine is simple, fast, and has high efficiency. The main machine assembled by frame, the main transmission device, pressure devices, Roller Conveyor, and electrical control system, etc. Rack uses welding structure and eliminates stress; it has compact structure and beautiful appearance. Main gear from the motor through the Cycloid reducer driven roller main transmission operation achieved. Reduction of electrical devices -- cycloid gear reducer -- silk mother movements -- movements Roller. Roller Conveyor machine installed in the correct input and output terminal. Its correction is a process through Roller main transmission and constitute a lever-style groove, when H-steel flange plate through the hole at the correct pressure roller pressure, the flanges produced distorted, through elastic deformation, will be able to resume attain the correct shape.