1. summarize

1.1 Windmill tower is special equipment for power station. These equip ment all are produced by some steel plate , in this process widely used various welding machine .

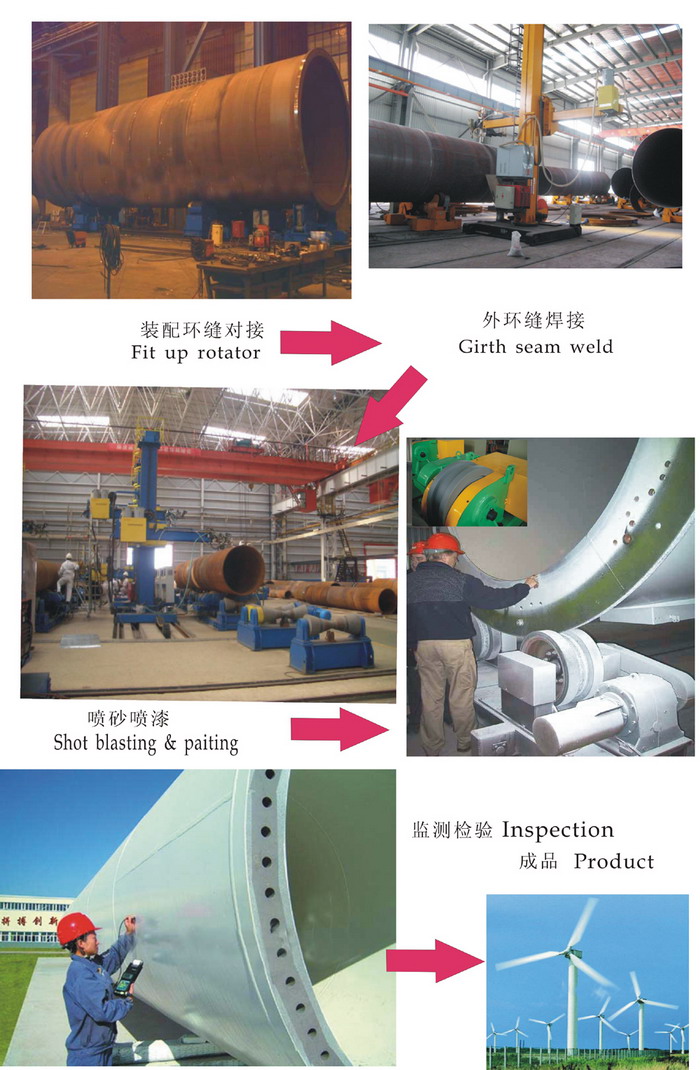

Its process including: cutting plate-----àmilling edge-----àroller bending(coiling plate)-----àSTT tack welding (Surface Tension Tranfer weld way)------àfilling welding---àcover welding (for single tank pieces ) ----àbottom Flange manual Fit up and Welding ----à Intermediate Flange Fit up and Welding TO STUB SHELL --------àFit up (for two or more tank )-----àinternal SAW-----àexternal welding SAW----forming whole product

PIPE Specifications:

800mm diameter to 5500mm diameter

12mm– 35mm Max 40 mm Thickness

3mstandard length of pipe (extended to maximum of 80m)

2.process detail

Step by Step Process -----Windmill tower Manufacture (refer attached process flow drawing about distance is from left to right and welding manipulator NO1 called WM1)

2.1 when the plate finished cutting according to tower diameter, then start to milling its edge , at last making one tank type through roller bending machine.

2.2 hang crane move the semi-manufactured goods to the Position 1 (hereinafter called P1), start tack & seal operation and finished STT CO2 shield tack welding , here including welding manipulator WM1—WM6050, welding rotator WR20 , Lincoln CO2 welder system.

2.3 P2, in this zone will finish the filling welding for each tank , welding internal & external seam then move the Position 3. here including welding manipulator WM2—WM6050, welding rotator WR20 , Lincoln SAW Tandem DC-1000 system.